◎欢迎参与讨论,请在这里发表您的看法、交流您的观点。

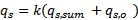

(1)

(1) (m³/h): total water supply for steam boilers with maximum steam load

(m³/h): total water supply for steam boilers with maximum steam load (m³/h): other water consumption, such as continuous sewage discharge, regular sewage discharge, desuperheater water consumption and etc.

(m³/h): other water consumption, such as continuous sewage discharge, regular sewage discharge, desuperheater water consumption and etc. (3)

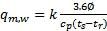

(3)  ( kg/h): mass flow of circulating water pump in hot water boiler room

( kg/h): mass flow of circulating water pump in hot water boiler room◎欢迎参与讨论,请在这里发表您的看法、交流您的观点。