◎欢迎参与讨论,请在这里发表您的看法、交流您的观点。

Product Introduction

In order to satisfy our customer and speed up the development of the high efficiency multistage pump, the high-efficiency pump adopts the advanced technology from home and abroad. We use the high efficiency and energy-saving hydraulic model recommended by the state. And developed according to the standard of the API610. Being the leading position in the pump industry. The series of this pump are more wide performance and high-efficiency area, work steady and safety, low noise, easy for maintaining, less easy wearing out parts. It can work three times non-failure operation time than common pump. So it greatly reduced the cost, and the operation hours of the pump.

High efficiency self-balance sectional centrifugal pump is innovated according to the traditional multistage centrifugal pump, declare the multistage axils force balance set. It is the best substitutes of the type D, DG multistage centrifugal pump with the balance disk. As without the balance disk, so no disk clash and no backflow lose of the balance disk. So the efficiency of the pump is 3-12% higher than the similar type pump, at the meantime, the totally solved the problems of rotor seizure caused by the lose effectiveness of the balance disk, great extend the life of the pump. Long time operation proved that this series pump has reached to advance technology of the similar type pump in China.

Main Design Point

High-efficiency self-balancing multistage centrifugal pump, it’s design is based on the actual safety, economy, failure-free operation ability and low repair and maintenance cost of the whole operation of the pump set. The main design point introduction as below:

Main Applications

• corrosive liquid conveying for oil chemical industry

• corrosive liquid conveying for coal chemical industry

• corrosive liquid conveying for coal chemical industry

• corrosive liquid conveying for chemical plant

• For chemical processing

Technical Data

| Product Name | DF(P) Self-balancing Corrosive Resistance Multistage Pump |

| Structure | Multistage |

| Material | Cast Iron/Stainless Steel/Ductile Iron |

| Head | 75-1440m / 246-4724ft |

| Flow | 6.3-1100m³/h / 27.7-4840USgpm |

| Temperature | -20℃~105℃/ -4~410℉ |

| Speed | 1480r/min & 2950 r/min |

| Power | 5.5-4500kw |

| Efficiency | 32%-84% |

| NPSH | 2-7 m |

| Liquid Medium | Corrosive liquid |

| Standard | ISO9001 |

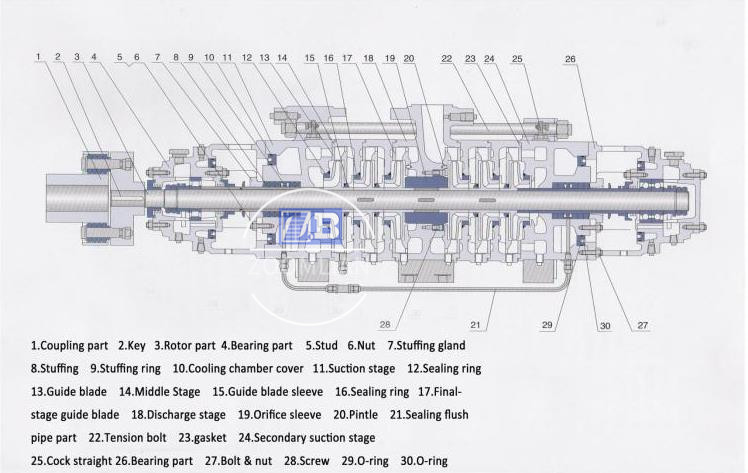

Structure Chart

Model Description

DF 46-80× 12JA(P)

DF ---------------------------- Multistage corrosion resistance centrifugal pump

46 --------------------------- The designed flow: 46 m3/h

80 --------------------------- The single stage head: 80 m

12 ---------------------------- Number of impellers

J ------------------------------Mechanical seal

A ------------------------------Impeller has been cut for the first time

P ---------------------------- Self balancing structure

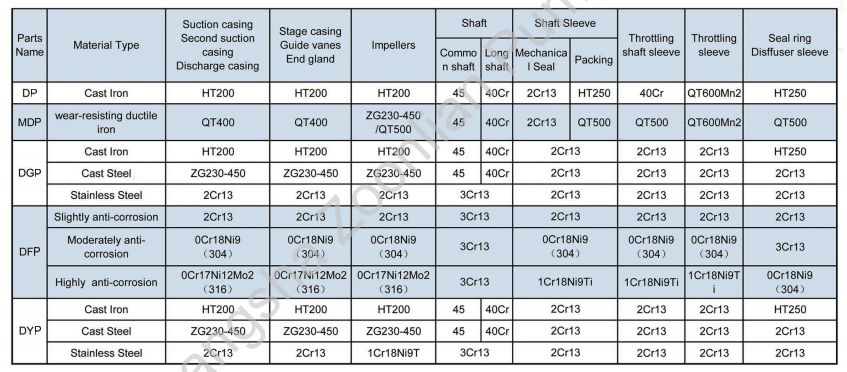

Material Of Pump Parts

◎欢迎参与讨论,请在这里发表您的看法、交流您的观点。