◎欢迎参与讨论,请在这里发表您的看法、交流您的观点。

Product Brief Introduction

Type S pump belongs to single-stage double-suction split centrifugal pump. It transfers clear water or pure liquids physically and chemically similar to clear water. This type pump may be used as a drainage or water supply pump in factories, mines, cities ,generating stations and hydraulic engineerings, and also as a circulating pump in thermal stations or as a drainage and irrigation pump in agriculture.

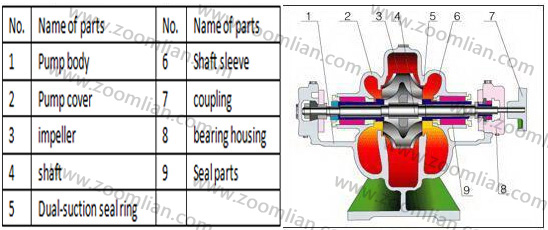

Structure Description

1. The inlet opening and outlet opening of type SA pump are all cast horizontally in the pump body are vertical to the pump shaft centerline. The pump body is separated horizontally from the pump cover in order to inspect the inner parts without disconnecting the pipe lines and the motor(or other prime movers Looking from the motor, the pump runs in anti-clockwise direction.

2. The main structure is identical except the bearing and the sleeve.

Constructions of bearing:

Some of the pumps are mounted with ball bearings, lubricated by filling oil the through the oil cups or by spattering oil from the oil rings; and the others are mounted with a babbiting -lined sleeve bearing to every end of each shaft without the coupling half. The axial thrust of a double suction pump is basically balanced, while a smaller amount which has not yet been balanced is supported by a single row radial ball bearing.

Constructions of shaft sleeve:

For some pumps, the sleeve with screw thread serves as the nut to fix the impeller; for some pumps, each end has two sleeves, of which one with the screw thread; for some pumps, the sleeve nut may fix the sleeve and impeller.

3. The main parts: casing, casing cover, impeller, shaft, wearing ring, shaft sleeve, bearing box, bearing, packing sleeve, packing ring and so on.

Most of the parts of the pump are made of cast iron, except that shaft is of quality carbon steel and stud, bolt ,nut and key are of steel.

The impeller, the wearing ring and the shaft sleeve placed in the packing are all easily wearing parts, and may be replaced with spare parts when wearing off.

The bearing with the oil cup is lubricated with grease, the other lubricated by spattering oil from an oil ring is greased with spindle oil No.2 or No.3.

Technical Data

| Product Name | Split case centrifugal pump |

| Structure | Single stage |

| Material | Cast Iron |

| Head | 11-216m / 36-708ft |

| Flow | 72-20106m3/h / 316.8-88466USgpm |

| Temperature | 0~150 ℃ / 0-302℉ |

| Speed | 730-2950r/min |

| Power | 18.5-850kw |

| Efficiency | 12%-88% |

| Liquid Medium | Various medium based on the material |

| Standard | ISO9001 |

| NPSH | 3.8-8.7 m |

Structure Chart

Model Description

300 S (SR/SM/SF/SY) 19 A

300 ----------------- Inlet diameter 300 mm

S -------------------- Split case centrifugal pump

SR -------------------Split case centrifugal hot water pump

SM -------------------Split case centrifugal abrasive resistance pump

SF -------------------Split case centrifugal corrosion resistance pump

SY -------------------Split case centrifugal oil pump

19 ------------------- Head 19 m

A -------------------- A, B, C separately represents that outer diameter of impeller is changed the first, the second and the third time

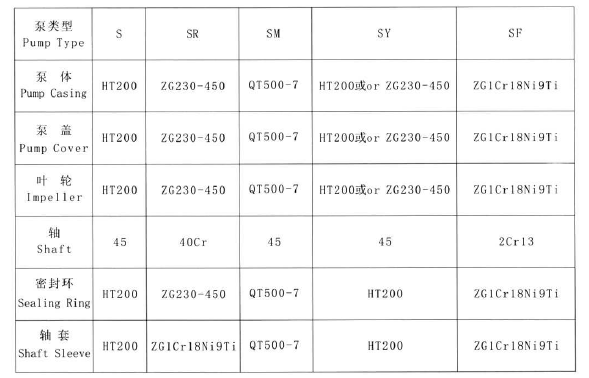

Pump Parts Material

◎欢迎参与讨论,请在这里发表您的看法、交流您的观点。